|

|

|

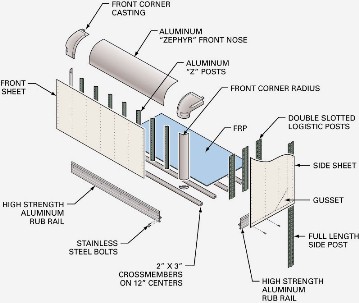

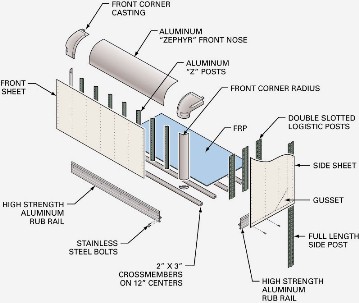

| Front-

Aerodynamic front radius with heavy duty corner

castings (not fiberglass), 5" front corner radius utilizing

1/8" rugged aluminum extrusion. |

|

| Walls-

Walls Aluminum (.040 in.) panels, pre-painted white, baked

enamel (.050 in. optional). |

|

| Posts

- Double slotted galvanized steel logistic posts on 24"

centers (16" optional). |

|

| Roof

- One-piece aluminum (.032 in.), tension-fitted and bonded to

roof bows, perimeter riveted. Roof assembly bolted to top rail

structure for easy removal and repair. |

|

| Roof

Bows - Roll-formed 18 gauge galvanized steel,

anti-snag configuration, located on 24" centers |

|

| Rear

Frame -Rear Frame 11 gauge (1/8" nominal thickness)

galvaneal steel with reinforcement at all stress points.

Tapered rear threshold for proper water run-off. |

|

| Doors

- Custom built side or rear swing doors ensure a precise fit

and positive closing, with quality 13mm thick DuraPlate

exterior skin construction on rear doors and 6mm thick skins on

side doors. |

|

| Door Hinges

- Heavy-duty extruded aluminum side and rear door hinges

with replaceable stainless steel pins for the best possible

long term use.. |

|

| Crossmembers

- Hi-tensile 3 inch I-beams on 12" centers (not 16"), double

bolted with stainless steel fasteners at each end to the

heavy-duty extruded aluminum rub rail. Alternating crossmembers are

gusseted to longitudinals, and steel wheel pans provide

support over the rear wheels. |

|

| Longitudinals

- Structural steel C channel (height dependent on chassis

mounting requirements). |

|

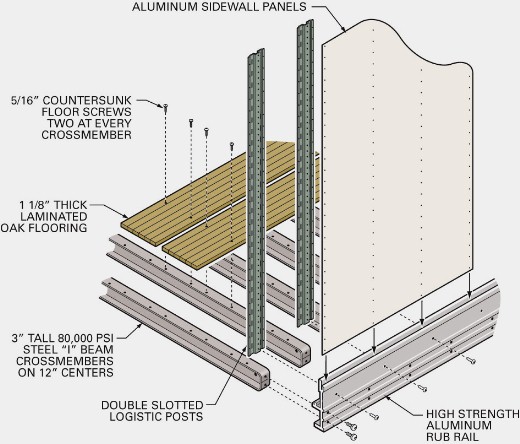

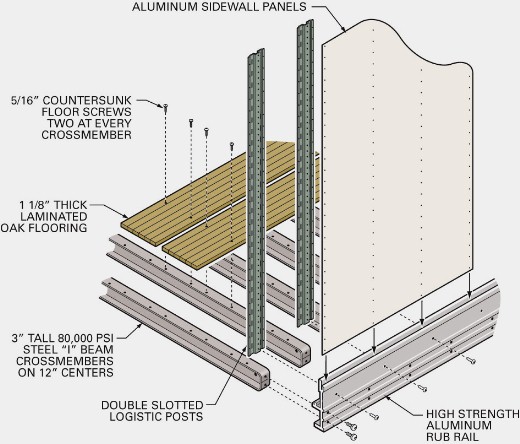

| Floor

- 1 1/8" oak hardwood, each board installed with two 5/16" countersunk

screws at each crossmember and securely joined to adjacent boards

by shiplap joints and an added crusher bead to ensure a tight

seal. Entire floor is coated with multiple coats of polyurethane varnish. |

|

| Lining

- 1/4" plywood on sides and front wall. |

|

| Interior

Light - Roof-mounted dome light, recessed switch in

wall inside rear door opening. |

|

| Exterior Lights - Marker lights recessed in roof cove

with exterior wiring in protective groove. All connectors shielded

from moisture by heat-shrink insulators. |

|

| Reflectors

-

Installed as required to comply with FMVSS. |

|

|

Undercoating -

Petrol base (not paint) on full understructure. |

|

|

Mounting -

Body mounted on customer-supplied chassis. Hardwood filler strips

are steel-banded to top of the chassis frame rails. Zinc plated

U-bolts are placed through crush pipes (between frame rails).

The U-bolts secure the body to the frame, and crush pipes

prevent over-tightening

and bending of frame rails. Structural steel side-standards

are welded to longitudinals to prevent any side-to-side

shifting.

|

|

|

Mudflaps -

U.S. Truck Body |

| |

|

|

| |

|

DuraPlate®

and Stainless Steel |

| |

|

|

|

|

|

| |

|

|

|

| U.S.

Truck Body swing doors set a new industry standard for

quality. We custom build all rear and side swing doors with the

finest materials and workmanship so you can expect a precise fit, positive

closing, and long lasting quality. |

|

|

We start with DuraPlate® panels - exceptionally strong,

lightweight, and resistant to damage, leaks, and corrosion.

These door panels are composed of 80,000 psi yield steel

skins. DuraPlate® panels

resist scrapes, punctures, buckling, and permanent deformation. The polyethylene core and the bond between the skins and core

form an added barrier that won't deteriorate and is impervious

to water. With no plywood construction, there's nothing to rot.

|

|

| Then

we add stainless steel bar locks & latches along with

premium heavy-duty extruded aluminum hinges with replaceable

stainless steel pins. |

|

| At

U.S. Truck Body, we build doors to last, and we put this same

attention to detail into every other part of our bodies. When

you purchase a body from us, you'll get one designed to outlast

your chassis, so today's appearance will equal 10 years' appearance.

|

|

|

|

|

Strongest Peak in

the Industry |

|

|

|

|

We've designed our peaks for maximum size and load capacity.

Heavy extruded aluminum rails are gusseted to steel logistic

posts to form a full extension on each side of the peak.

An FRP panel fits firmly into the side and front rails and is

further supported from underneath with 2" x 3" aluminum

crossmembers. The extruded aluminum radius corners tie

together the front posts and panels to the side walls to

complete one of the strongest peaks in the industry. |

| |

|

Finished

Oak Hardwood Floor |

|

|

|

| We

use 1 1/8" thick laminated oak flooring as our

standard moving van body floor, installed with two 5/16" countersunk screws

per board at each crossmember. Each board is joined using ship-lap

joints with an added crusher bead to ensure a tight fit. Then

the entire floor receives multiple coats of polyurethane varnish

for lasting protection. As an option, screw holes are

filled and sanded prior to varnishing. |

|

|

| |

|

Crossmembers

- 80,000 psi hi-tensile steel "I" beams are double bolted at

each end to the heavy-duty extruded aluminum rub rails.

Alternating crossmembers are gusseted to longitudinals, and

steel wheel pans add support over the rear wheels. Double

slotted galvanized steel logistic side posts are used on 24" (or

optional 16") centers with 1/4" plywood panels recessed between

the posts as our standard construction. |

| |

|

Roof

Structure |

|

|

|

|

Our unique two-piece roof/rail system is designed for strength

and durability. Heavy-duty one-piece translucent or

aluminum sheeting is tension fitted and bonded to 18 gauge

galvanized steel anti-snag roof bows. Each roof bow is

double-riveted to extruded high-strength aluminum alloy roof

coves. This design not

only increases structural integrity, it also means the roof

can be easily replaced (if damaged) without disturbing the sidewall

structure. For additional strength, we use a

fuel-efficient "Zephyr" front nose and heavy-duty cast aluminum

(not plastic) corners. The aerodynamic design reduces air resistance and

helps deflect overhanging tree branches. |

| |

|

Rear

Frame |

|

|

|

|

To withstand the tough loading conditions of moving

professionals, we build our frames with heavy-duty, 11 gauge galvaneal steel and reinforce all internal

and external stress points with steel plates (shown in yellow

on the drawing). A tapered sill

provides proper water run-off. Stainless steel frames

are also available as an option. Assembling each frame in

a spinner jig allows welding to be done on a horizontal plane to

ensure the best possible weld penetration. |